The Importance of an **Injection Mold Company** in Today's Manufacturing Landscape

In the rapidly evolving world of manufacturing, the role of an injection mold company cannot be understated. As businesses increasingly look for innovative solutions to enhance their production capabilities, injection molding stands out as a dominant technique for creating high-quality products efficiently and economically. This article explores the various dimensions of injection molding, its benefits, and why teaming up with a reliable injection mold company is essential for modern manufacturers.

What is Injection Molding?

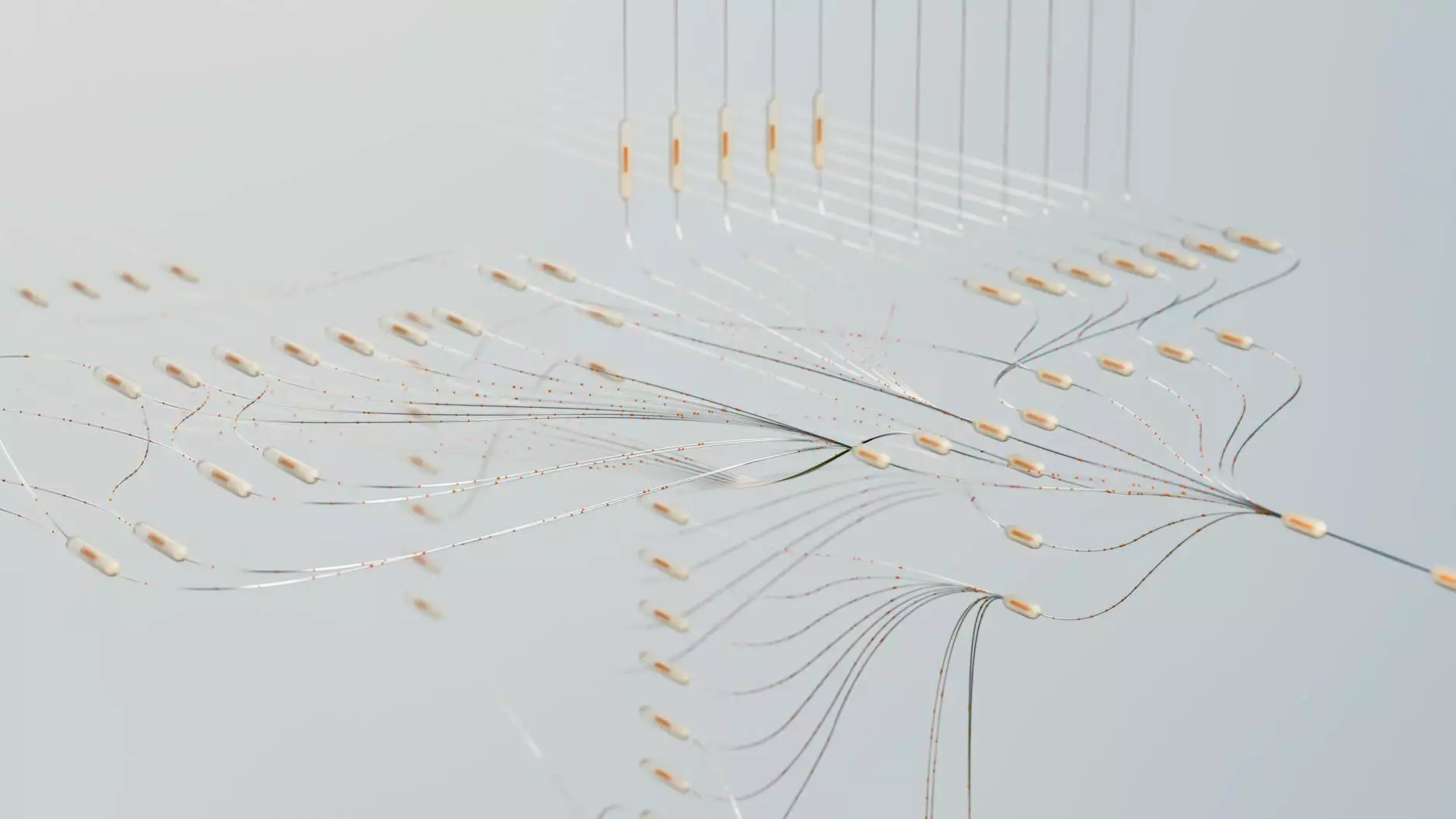

Injection molding is a manufacturing process that involves the injection of molten material into a mold. Once cooled, the material solidifies, forming a precise shape that can be used in a wide range of applications. The techniques used by an injection mold company are integral to producing components in various industries, including automotive, consumer electronics, medical devices, and more.

The Process of Injection Molding

The injection molding process can be broken down into several key stages:

- Material Selection: The first step involves selecting the appropriate thermoplastic or thermosetting materials suitable for the desired product.

- Injection: The chosen material is heated until it reaches a molten state and is then injected into a mold under high pressure.

- Cooling: Once injected, the material is allowed to cool and solidify, taking the form of the mold.

- Demolding: After the cooling phase, the mold opens, and the finished product is ejected.

- Post-Processing: Finally, additional processes might be needed, such as trimming, painting, or assembling components.

Advantages of Utilizing an Injection Mold Company

Partnering with a dedicated injection mold company provides numerous benefits that streamline manufacturing and enhance product development:

1. Cost Efficiency

Injection molding is one of the most cost-effective manufacturing processes, particularly for large-scale production. The initial investment in machinery and mold design can be substantial, but the cost-per-unit decreases significantly with increased production volumes.

2. High Precision and Quality

The precision of injection molding is unparalleled. With the use of advanced technology, an injection mold company ensures that every product meets defined specifications, resulting in minimal waste and maximum quality.

3. Versatility

Injection molding can accommodate a wide variety of materials, including plastics, metals, and even glass. This versatility allows businesses to innovate continuously and customize products according to market demands.

4. Speed of Production

Once the molds are created, the actual production cycle is remarkably quick. This speed enables companies to bring products to market faster than traditional manufacturing methods.

Why Choose DeepMould.net as Your Injection Mold Company?

When selecting an injection mold company, it is essential to consider experience, technology, and customer service. DeepMould.net excels in all these areas:

Expertise and Experience

With years of experience in injection molding, DeepMould.net has perfected the art of delivering high-quality products. Our team of experts is knowledgeable in the latest technologies and best practices in the industry.

State-of-the-Art Technology

Utilizing advanced machinery and software ensures that our processes are as efficient and precise as possible. This commitment to technology allows us to meet the diverse needs of our clients.

Customer-Centric Approach

At DeepMould.net, customer satisfaction is our top priority. We work closely with our clients to understand their requirements and provide customized solutions that align with their goals.

Applications of Injection Molding in Various Industries

The applications of injection molding are vast and varied. Below are some of the industries that greatly benefit from this manufacturing technique:

1. Automotive Industry

Injection molding is widely used in the automotive sector for producing components like dashboards, bumpers, and trims. The high durability and lightweight characteristics of molded parts improve vehicle performance and fuel efficiency.

2. Consumer Electronics

With the demand for high-quality electronic devices on the rise, injection molding provides a reliable method for producing housings, connectors, and various other components with precision and speed.

3. Medical Devices

In the medical field, the need for precision and compliance with safety standards is critical. Injection molding allows for the mass production of medical devices, ensuring consistency and reliability.

4. Packaging Industry

Injection molding plays a crucial role in manufacturing caps, containers, and packaging solutions that protect and preserve products while also being cost-effective.

Future Trends in Injection Molding

As technology continues to evolve, so does the injection molding industry. Some emerging trends include:

- Smart Manufacturing: The integration of IoT and smart technologies enhances monitoring and control over the injection molding process.

- Eco-Friendly Materials: The industry is shifting towards bioplastics and recyclable materials to meet growing environmental concerns.

- Additive Manufacturing: The combination of injection molding with 3D printing techniques is paving the way for more innovative product designs.

Choosing the Right Injection Mold Company: Key Considerations

When it comes to selecting an injection mold company, there are several factors businesses should take into account:

1. Quality Assurance Practices

Ensure that the company follows strict quality control measures and has relevant certifications that guarantee product quality.

2. Design Capabilities

Evaluate the company's ability to assist with mold design and optimization, as these factors can significantly affect the final products.

3. Production Capacity

Assess whether the company can meet your production demands in terms of quantity and timelines, especially for large-scale projects.

4. Support and Communication

Open lines of communication and reliable customer support are vital throughout the manufacturing process. Choose a company that is approachable and willing to assist you with queries and concerns.

Conclusion

The importance of partnering with a trusted injection mold company like DeepMould.net cannot be overstated. The advantages of injection molding in terms of cost-efficiency, precision, and production speed make it an indispensable process in the manufacturing industry. By understanding the intricacies of injection molding and aligning with an experienced partner, businesses can not only enhance their product offerings but also secure a competitive edge in their respective markets.